Warehouse Racking System

TTF Automated Storage & Retrieval System

TTF Automated Storage & Retrieval System

Descriptions :

ASRS Concept Structure

- Beams / Bracket type racking with high steel quality for whole assembly structure.

- Steel pallet to load goods with strong loading capacity and better rigidity.

- Main components of racking being manufactured in high precision production.

- Installation done by certified engineers and technicians at site.

ASRS Benefit Highlights

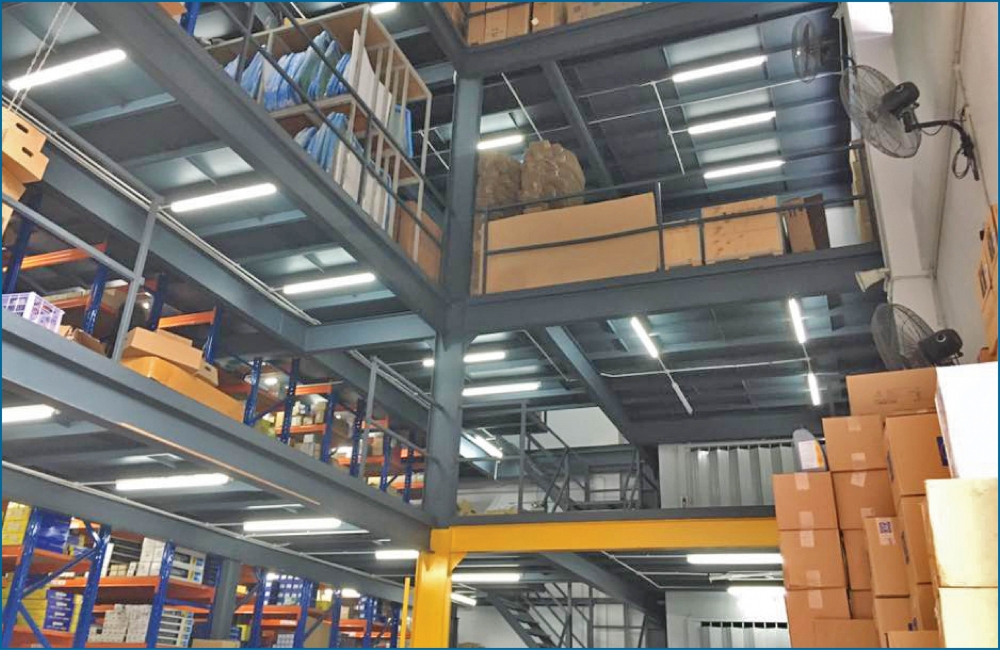

- High storage density degree vs space.

- Increased variety of goods stored.

- Micro warehouse cells stock check.

- Maximum store space utilization.

- High rise warehouse structure.

- Minimum land space utilization.

- High automatic operational speed.

- Minimum manual stock handling tasks.

- Minimum stock damages and losses.

- Application for industry 4.0 implementation.

- Interface syncing with mainframe ERP / SAP.

- Auto database logs and ISO reporting formats.

- Real time inventory management.

- Increased inventory stock accuracy.

- Increased warehouse overall efficiency.

- Short ROI period of approximately 2 to 3 years.

- High rate of increased operation efficiency.

- Skilled workers development via technology.

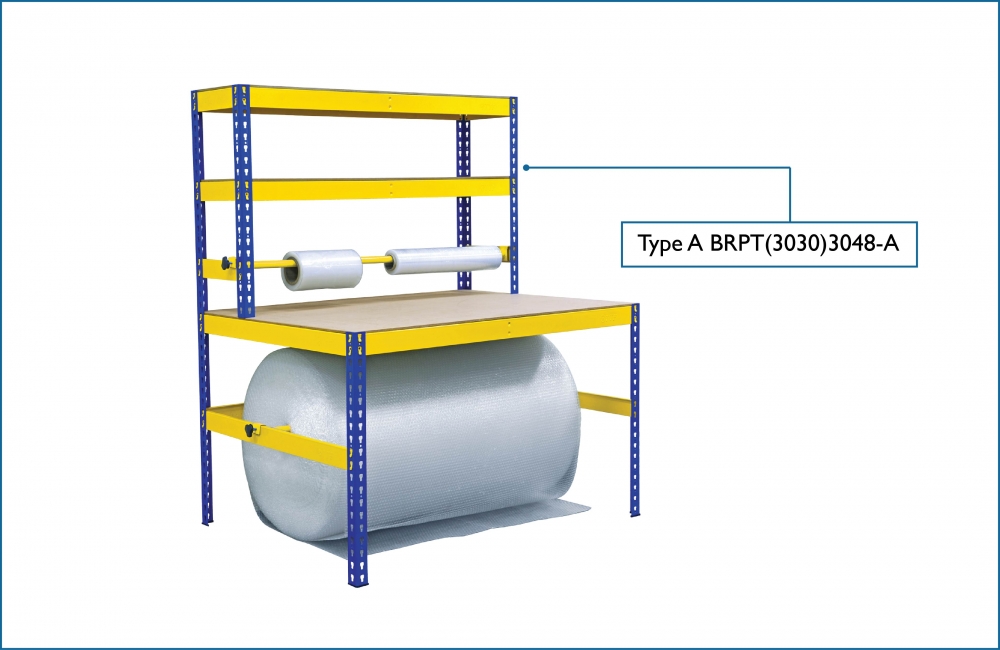

Custom Design System

Planning Stage

Custom design for warehouse layout and spacing optimization blueprint by site visits and technical discussions.

Designing Stage

ASRS components technical selection by engineers in engineering division to meet customer requirements.

Manufacturing Stage

Manufacturing of selected components according to configured mode and design drawings.

Installation Stage

Assemble, install & debug od mechanical structure and electrical control system at customer site.

After Sales Stage

Techincal support / services at site and remote online maintenance by professional engineers at your requests.

Design Highlights

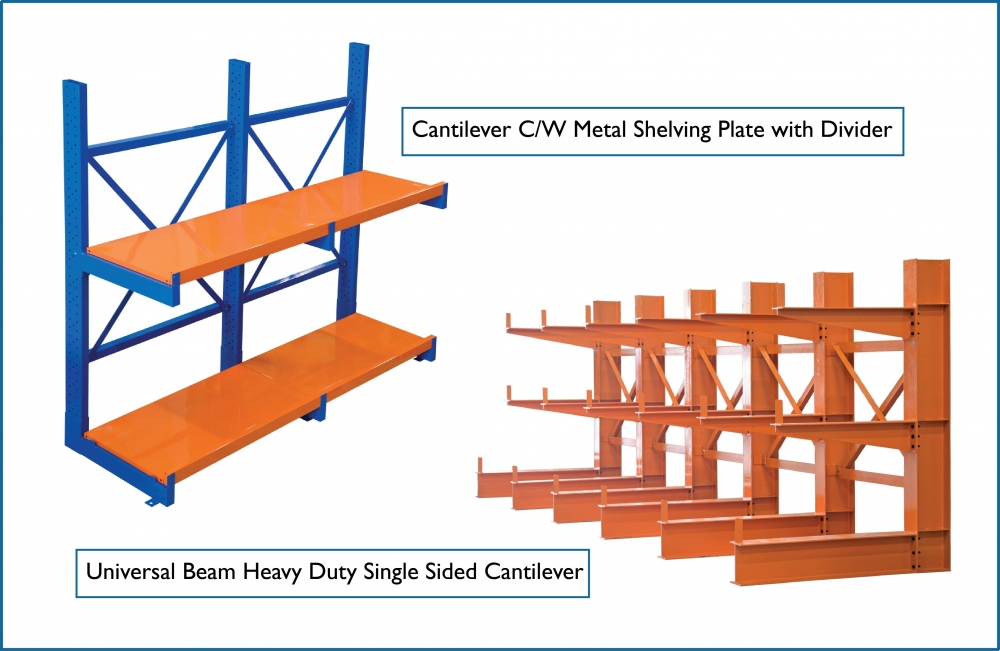

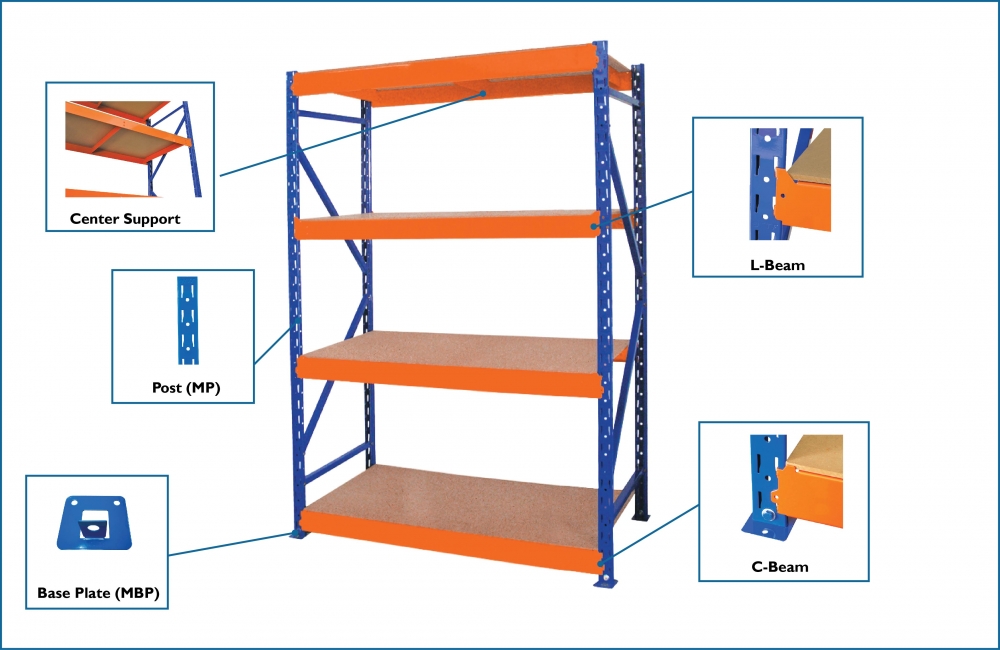

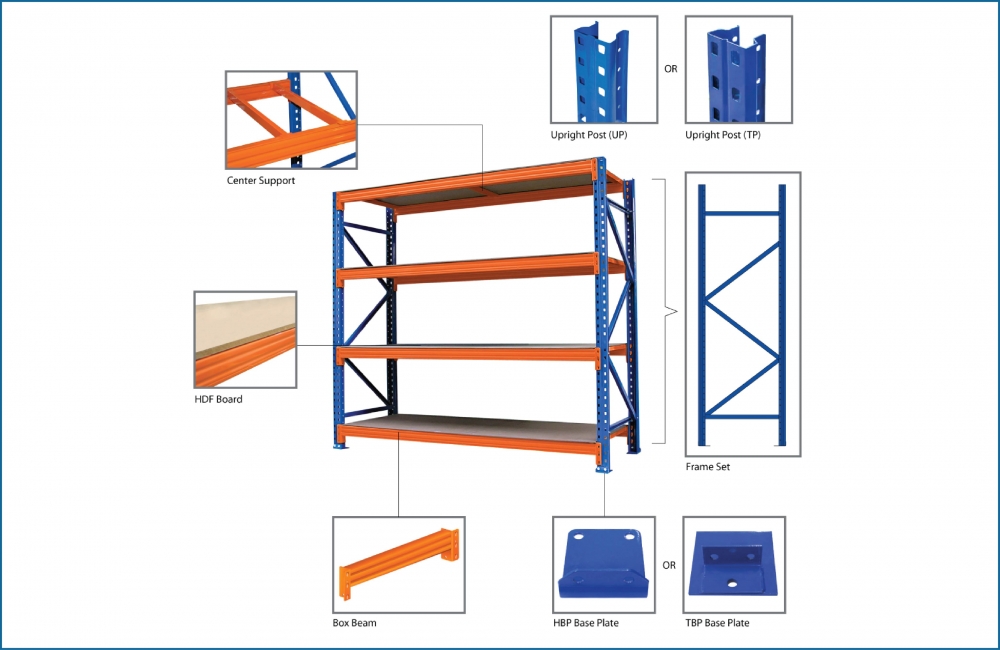

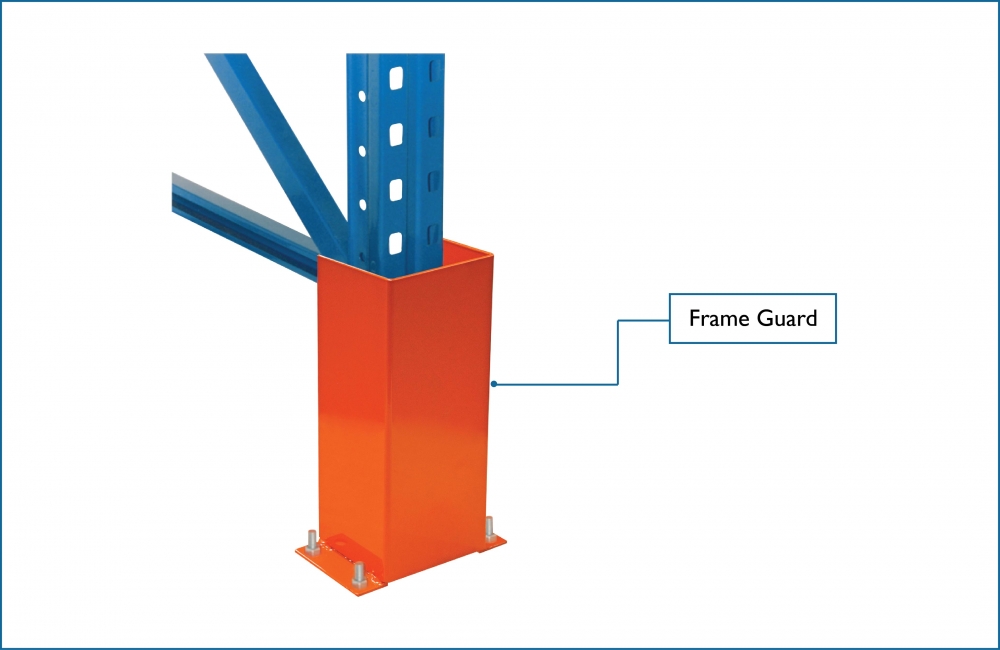

Racking System

- Optimized sectional design

- High quality steel material

- Pitch adjustable 75mm upright

- Strengthen by bolts & nuts

- High intensity & good stability

- Epoxy powder coated surface

Stacker System

(1) Operation control mode - Computer monitoring & controlling system

(2) Operator schema - Online auto / Manual / Maintenance mode

(3) Auto address mode - Laser / Rolling / Barcode addressing / Communication mode Infrared / Wireless

Stacker Crane

- Single / Double mast structure

- Stable & reliable operation

- Vector frequency driver

- Encoder position controlling

- Real time tracing of pallets

- Touch screen easy operation

Conveyor System

- Roller conveyor

- Chain conveyor

- Lift & transfer conveyor

- Palletizing conveyor

- Depalletizing conveyor

- AVG lane conveyor

- Shuttle lane conveyor